A1 Professional Asphalt & Sealing Llc for Beginners

Table of ContentsA1 Professional Asphalt & Sealing Llc for BeginnersGetting My A1 Professional Asphalt & Sealing Llc To WorkThe Single Strategy To Use For A1 Professional Asphalt & Sealing LlcNot known Details About A1 Professional Asphalt & Sealing Llc Some Ideas on A1 Professional Asphalt & Sealing Llc You Need To Know

They likewise allow the opportunity of area check and remove the possibility of sampling errors where the asphalt being used was not the like received by the testing lab. Simon Hesp, Queens College (Kingston, Ontario) The TFHRC group will certainly quickly send to AASHTO the draft examination approaches that transportation companies can make use of to examine for the presence of REOB in asphalt blends.is a senior study chemist on the Pavement Products Team in FHWA's Workplace of Framework Study and Development and Federal lab manager for the chemistry laboratory at TFHRC. He is a fellow of the Royal Culture of Chemistry in the United Kingdom and a Chartered Chemist. For more details, contact Terence Arnold at 2024933305 or .

Split filling is when warm sealer is made use of to load cracks in pavement to prevent water from doing anymore damage. The sealer will certainly stick to the asphalt, keeping water and various other natural environments from permeating and manipulating the weak point in your sidewalk. Among the largest errors individuals make when it concerns cracks in their sidewalk, is waiting too long to get them loaded.

The Of A1 Professional Asphalt & Sealing Llc

Sealcoating leaves your pavement looking streamlined and dark. This is the perfect option if you are looking for a basic means to improve the appearance of your asphalt and shield it from the elements. Extends life of sidewalk Increases the melting of snow and ice Decreases long-term fixing costs Secures sidewalk from oxidation, oil, chemical spills and water infiltration Enhances appearance of property Milling is the process of eliminating the leading layer of asphalt without disrupting the underlying subbase.

Milling can be completed at a portion of the price of a complete reconstruction since just the leading layer is removed and replaced. https://pastebin.com/u/a1asphaltseal. The entire procedure can be completed in a reasonably short duration of time. Inexpensive Rapid project conclusion Recycling of old product Patching is the procedure of filling out splits

Indicators on A1 Professional Asphalt & Sealing Llc You Should Know

All debris must be removed, periodically there might even be plant life jabbing with which should be gotten rid of from the root. asphalt sealcoating in st louis. Asphalt needs a sturdy base, or else, you'll just have much more problems in the future. The kind of asphalt utilized to fill splits will depend upon the weather and dimension of the pocket, usually warm or chilly mix asphalt will certainly be utilized

Depending on the size of the hole, various machinery or devices can be used for this. An asphalt overlay can be assumed of as a large patching task over a stretch of asphalt. Overlay is generally made use of when existing asphalt is showing some indicators of breaking and holes, yet not fairly enough damages to necessitate a complete substitute.

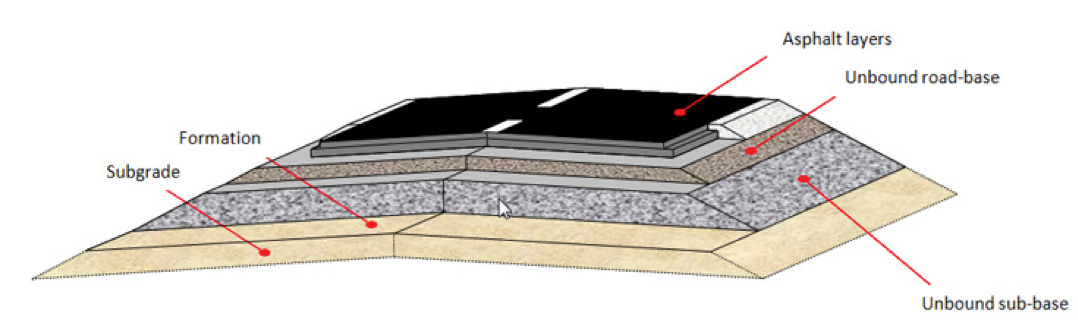

The sub base is the bottom most layer, it will be supporting your new pavement. A proof roll is a test to be sure the underlying surface is solid enough to support the brand-new asphalt.

A1 Professional Asphalt & Sealing Llc Fundamentals Explained

It's never far too late to find out something brand-new, and when it concerns asphalt pavement installment, there are lots of things that homeowners, business property proprietors, and community employees might not understand. At Wolf Paving, we are Milwaukee, Oconomowoc and Madison asphalt paving contractors in that take pride in informing people concerning whatever asphalt it's our passion.

The very first step in the asphalt installment process is to get rid of the existing surface, whether it is asphalt, concrete or pavers. Demolition and elimination is completed making use of hefty machinery, consisting of tiny bobcats and forklifts and when needed, front loaders and large dump vehicles. Particles is then gotten rid of. At Wolf Paving, we recycle the old asphalt and concrete in our asphalt plants, transforming weakening waste right into strong, functional brand-new asphalt.

The sub base supplies a secure surface to support new sidewalk. The below base is a frost barrier to help in reducing winter damage because of cold and thawing. Throughout the installment, base thickness, base stability, and compaction are necessary actions. If the sub base is not appropriately compacted, the asphalt surface on the top will certainly not give years of sturdiness.

Not known Factual Statements About A1 Professional Asphalt & Sealing Llc

Wolf Paving has actually likewise pioneered a brand-new process called raking. This process entails undercutting the sub base, yet rather of removing every one of the soft clay and soil, it is instead blended with added aggregate to boost the strength of the jeopardized areas - diagonal parking vs straight parking. As soon as the below base is laid and any soft locations are determined and fixed, it is time to add the binder